This page is dedicated to illustrating how our graduates use their skills in their everyday work and hobbies.

(Click photos to enlarge.)

Scott Sonksen, Lake of the Ozarks, MO

Degree: Tool & Die, AAS (1987)

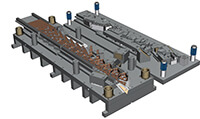

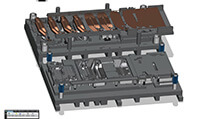

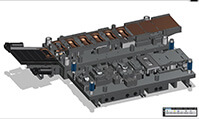

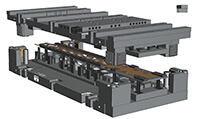

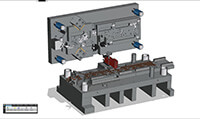

A friend directed me to look into a career in Tool & Die following high school. Immediately I was fascinated by the complexity of metal stamping dies and the craftsmanship required in becoming a journeyman. After attaining my degree through DMACC, I went to work as a Die Maker in a job shop in the Twin Cities. I jumped at a chance to move into a Die Design position at another local job shop, where I found my niche in life. As that company and opportunity grew, I trained other Die Makers to become Die Designers and enjoyed the ever-increasing challenges in complex stamping dies. As I moved from Minnesota to California and finally to Missouri, I've enjoyed the benefits from skills honed in the trade being utilized in my hobby as a car enthusiast. My love for creating unique, one-of-a-kind muscle and sports cars is as strong as my love of my career. In 2004, Velocity Design Service LLC was formed with my partner. We design progressive, transfer and stage metal stamping designs for a broad variety of industries for customers across the United States. We solely utilize Unigraphics NX software. The Tool & Die trade is truly a global one, where location does not hinder our ability to provide complex designs due to web-share communication and FTP file transfers. This would not be successful without the work ethic provided from a lifetime of dedicated and passionate pursuit of craftsmanship. I enjoy working from my home-based shop, where I have my Velocity office alongside my car hobby shop, complete with machine shop, welding, paint booth and hoist areas. I continue to have a hunger to acquire new skills in design and fabrication, as well as advocating the need for increasing US-based manufacturing.

Poster:

Velocity Design Service LLC was formed in 2004 as a contract design service for the Tool & Die industry. As a two-man, home-based business located at the Lake of the Ozarks in Missouri , we design progressive, transfer and stage metal stamping designs for a broad variety of industries for customers across the United States. Along with technical expertise, outsource services must excel at clear, concise and courteous communications. We pride ourselves in measuring each unique customer's situation and adapting our communications through use of telephone, email, web-shares and texting services. Understanding the balance between bombarding our customers with questions and the equally-concerning lack of asking critical questions is a skill we have honed. Visit us at

www.velocitydesignservice.com to learn more about our business.

Josh Evans, Auburn, IA

Degree: Tool & Die, AAS (2005)

I attended DMACC in Carroll and received a liberal arts degree. I then decided to enroll at Ankeny in the tool & die program. After a few semesters I used my machining skills to get a part-time job at

Certified Power in Des Moines. This gave me experience and helped to pay the bills while I was in college. After graduation I want to relocate back to my hometown area and since I am a sportsman and hunter what better job could be than manufacturing sporting equipment. I am employed full-time in a small arms manufacturing company called

Volquartsen Custom near Willey, IA. My job consists of programming CNC machines which include running a five axis lathe, vertical mills, and a wire EDM. We use Solidworks as our CAD software for all the new parts that are designed. We also use Gibbs CAD/CAM software for CNC programming. Without the schooling and all the training I went through at DMACC I would not be where I am today; working at a job I love.

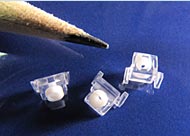

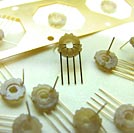

Jeremiah Miner

Degree: Tool & Die, AAS

I enrolled in the Tool & Die program at DMACC and also applied for the Accumold Scholarship before starting classes. After I received the Accumold Scholarship I was provided a part-time job while in college. Accumold® is a high-tech manufacturer of precision micro, small and lead frame injection molded plastic components. Utilizing processes developed from our Micro-Mold® technology, we design, build and produce unique molds and parts efficiently for markets that include Micro Electronics, Medical, Micro Optics, Automotive, and Military Applications. After completing the Tool and Die Program I then started working full-time at Accumold where I built and maintained plastic injection molds. I have since changed position in the company where I spend my time designing and programming electrodes using Mastercam. I have also been given the opportunity to teach Mastercam classes at DMACC. The Tool and Die program has opened so many new doors for me.

Brent J. Freeborn, Newton, IA

Degree: Tool & Die, AAS (2001)

I completed the Tool and Die program at DMACC in 2001. Following graduation, I worked as a tool maker at Williamsburg Manufacturing. I then moved to Ames where I started at

Technical Services, Inc. as a CNC machinist. Currently, I am living in Newton where I am an outside salesman for

Productivity, Inc. Productivity is based out of Cedar Rapids and distributes machining equipment and related tooling and accessories. I spend much of my free time fabricating cars for drag racing, which requires machining car components. The training I received from DMACC has been very beneficial in both my personal and professional life.

Jesse Nielsen, Soldier, IA

Degree: Tool & Die, AAS (2010)

I am now employed at

Malloy Electric in Sioux City Iowa. There I repair electric motors. We do welding and recutting of drive shafts, spray welding on bearing areas, sleeveing end bell castings and more. We also do some custom or as needed machine work. Most of this is done on lathes of all sizes. In my spare time I enjoy working on cars and motorcycles. Machining is a huge plus in this because I hope to one day bore my own blocks and grind valves. I have also used what I have learned in machining with every day repairs on my cars and such.

Bryan Compart, Lehigh, IA

Degree: Tool & Die, AAS (2006)

I am now employed atQuality Manufacturing in Urbandale, Iowa. I started working at Quality MFG as a CNC operator in my second year of college. Our company custom manufactures components and assemblies for other companies such as John Deere. After graduation I was offered a full-time position and I continue to work there today. In my current position I am responsible for setting up the machines and ensuring part quality, I also do CNC programming as the need arises. Our company continues to grow and we keep adding more equipment all the time. In my spare time I have many hobbies that relate to machining and fabricated parts. While I was in college I built a micro-mini pulling tractor just for fun (see pictures below).